Indian Motorcycle

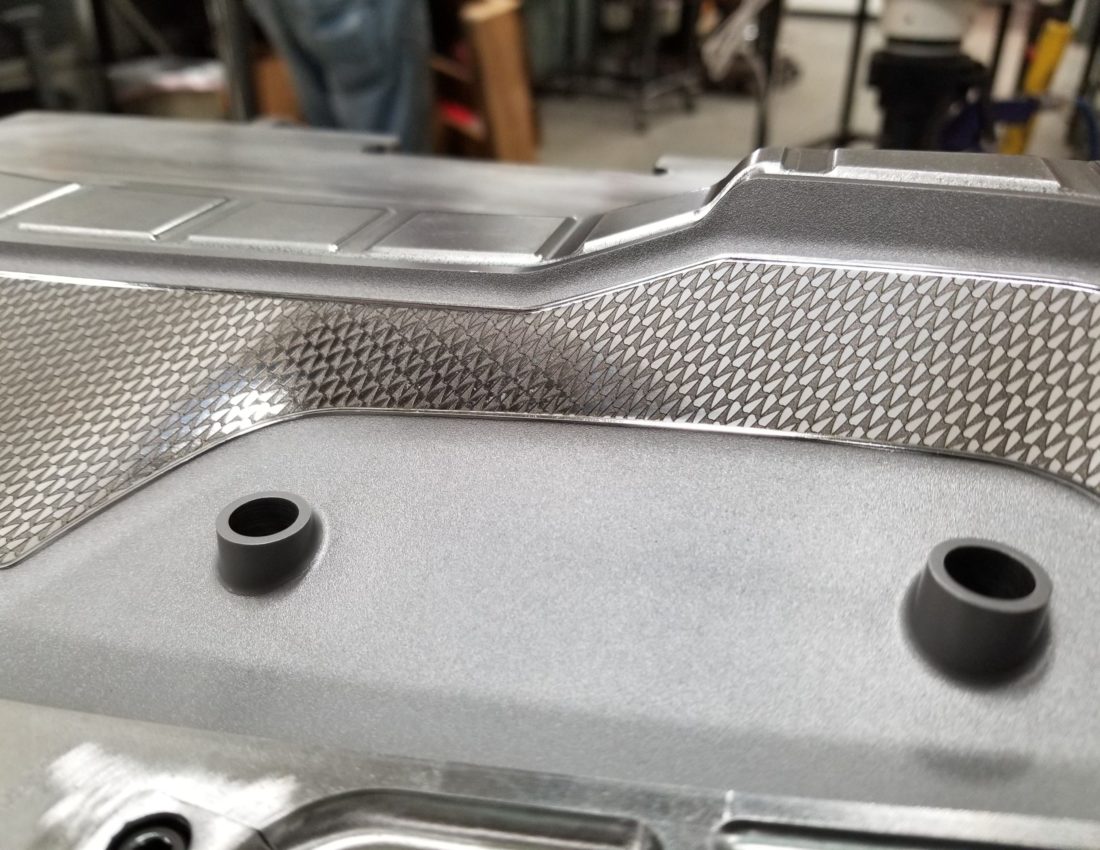

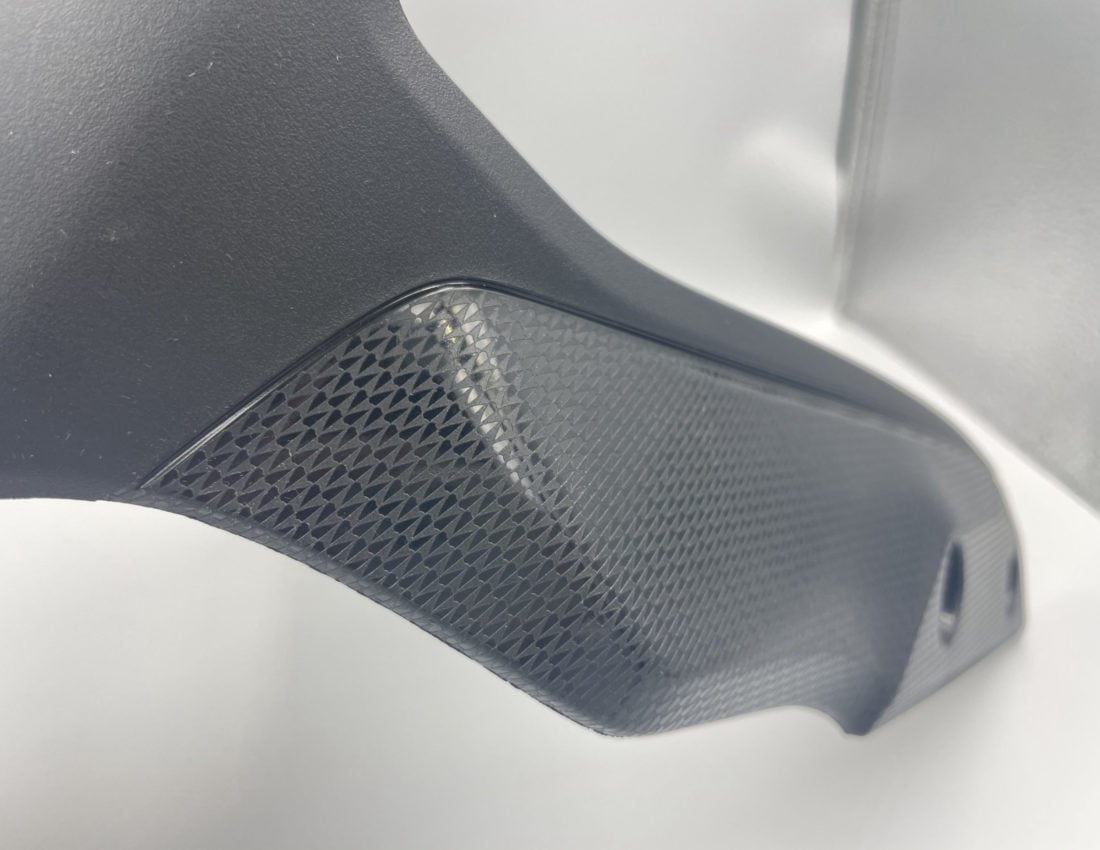

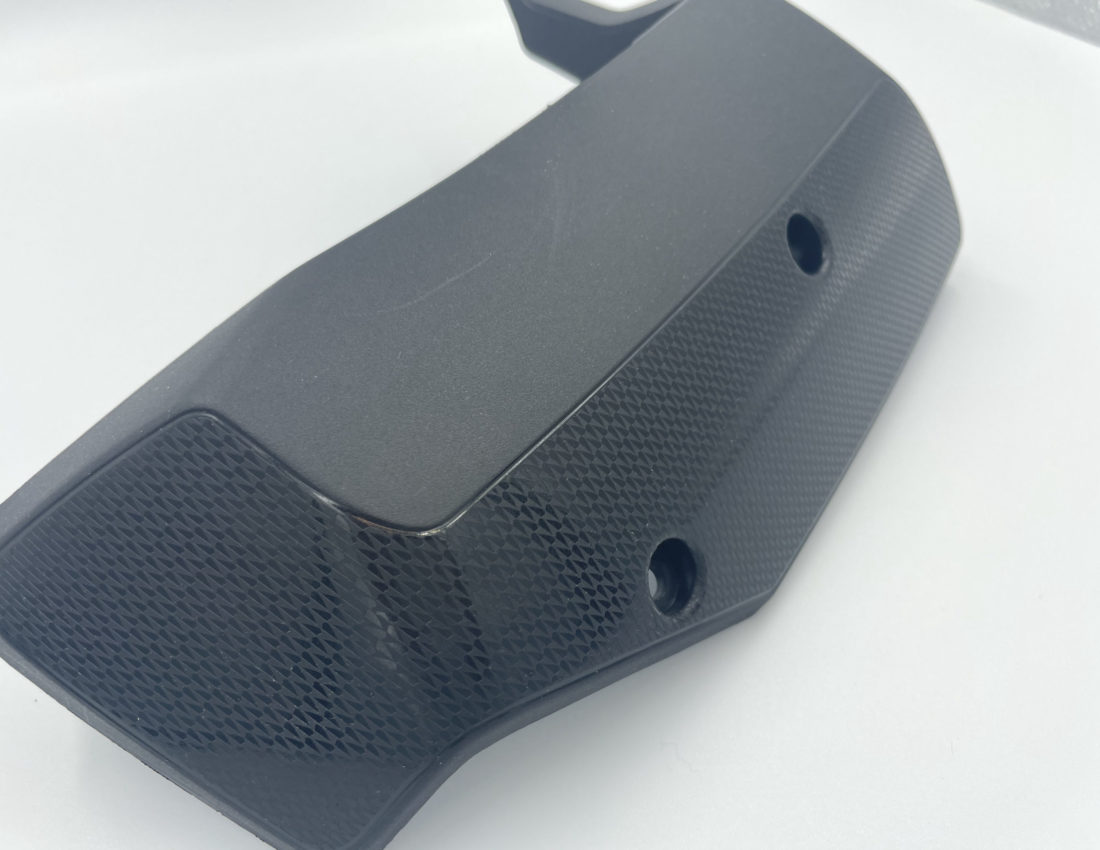

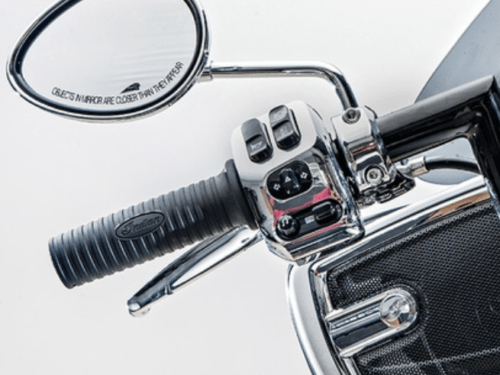

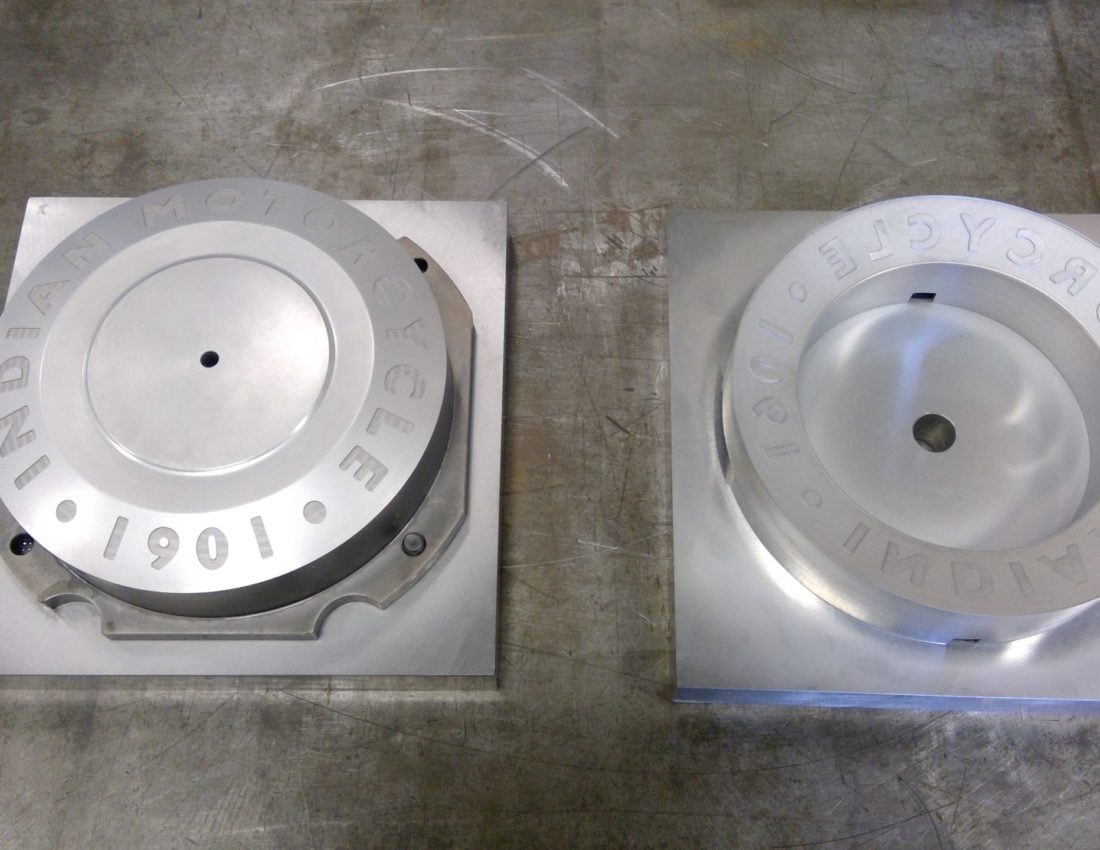

In this application example,  St Paul Engraving utilized several techniques and technologies to complete a multi-piece project for Indian Motorcycle. This type of unique project requires the use of laser texturing, chemical etching and laser marking. We laser textured a custom geometric pattern utilizing our laser 1200 on the bike’s mold cavities to help reflect Indian’s brand identity and chemically etched the mold to enhance the cosmetic appeal to the end user. We then laser textured and engraved a mold for Indian’s custom handle grips using our laser 1000. Next we engraved several different types of embossing dies for the bike’s badges and emblems. Finally, we serialized tank badges using our foba laser for laser marking.

St Paul Engraving utilized several techniques and technologies to complete a multi-piece project for Indian Motorcycle. This type of unique project requires the use of laser texturing, chemical etching and laser marking. We laser textured a custom geometric pattern utilizing our laser 1200 on the bike’s mold cavities to help reflect Indian’s brand identity and chemically etched the mold to enhance the cosmetic appeal to the end user. We then laser textured and engraved a mold for Indian’s custom handle grips using our laser 1000. Next we engraved several different types of embossing dies for the bike’s badges and emblems. Finally, we serialized tank badges using our foba laser for laser marking.