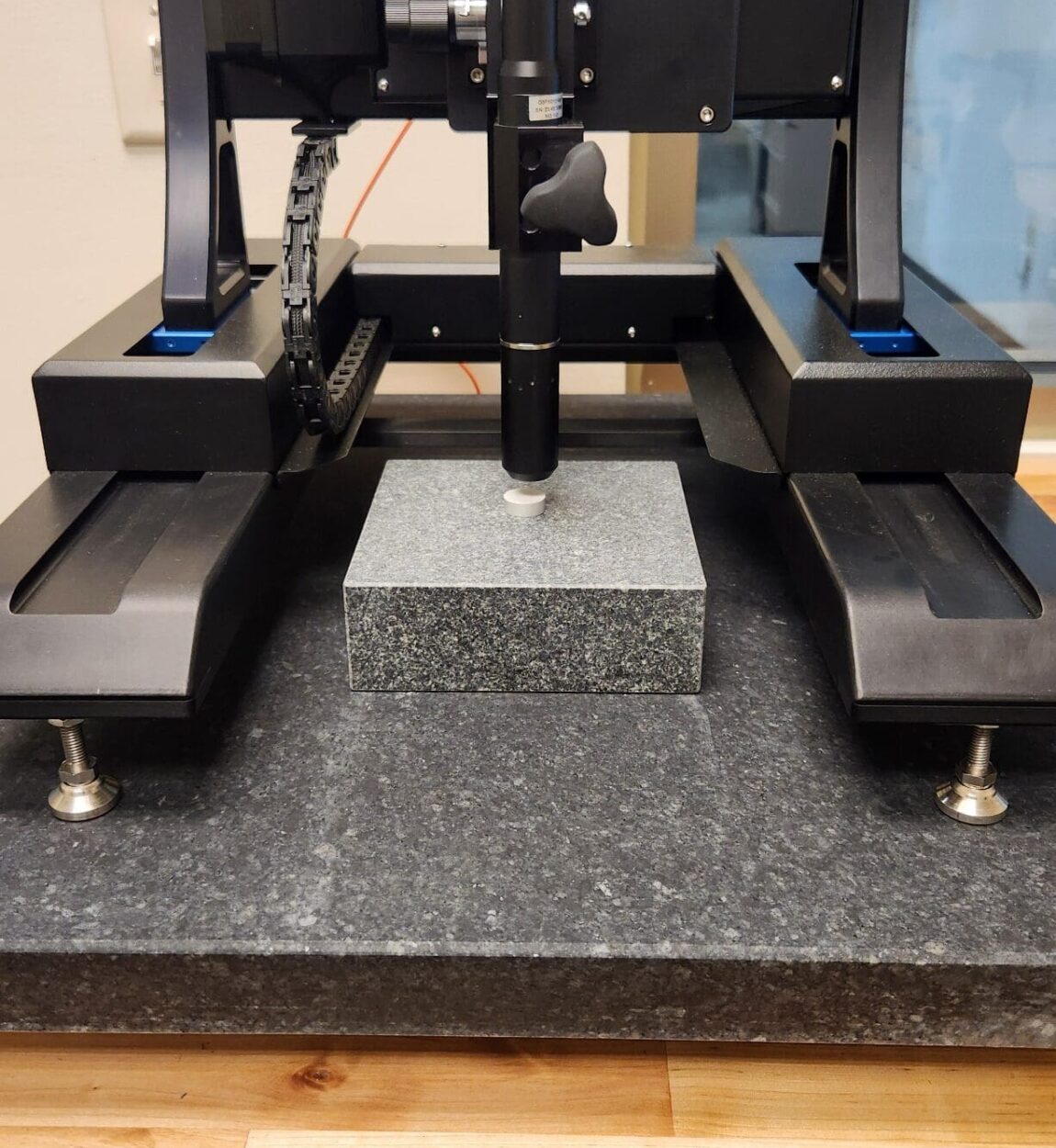

JR100 | Profilometer

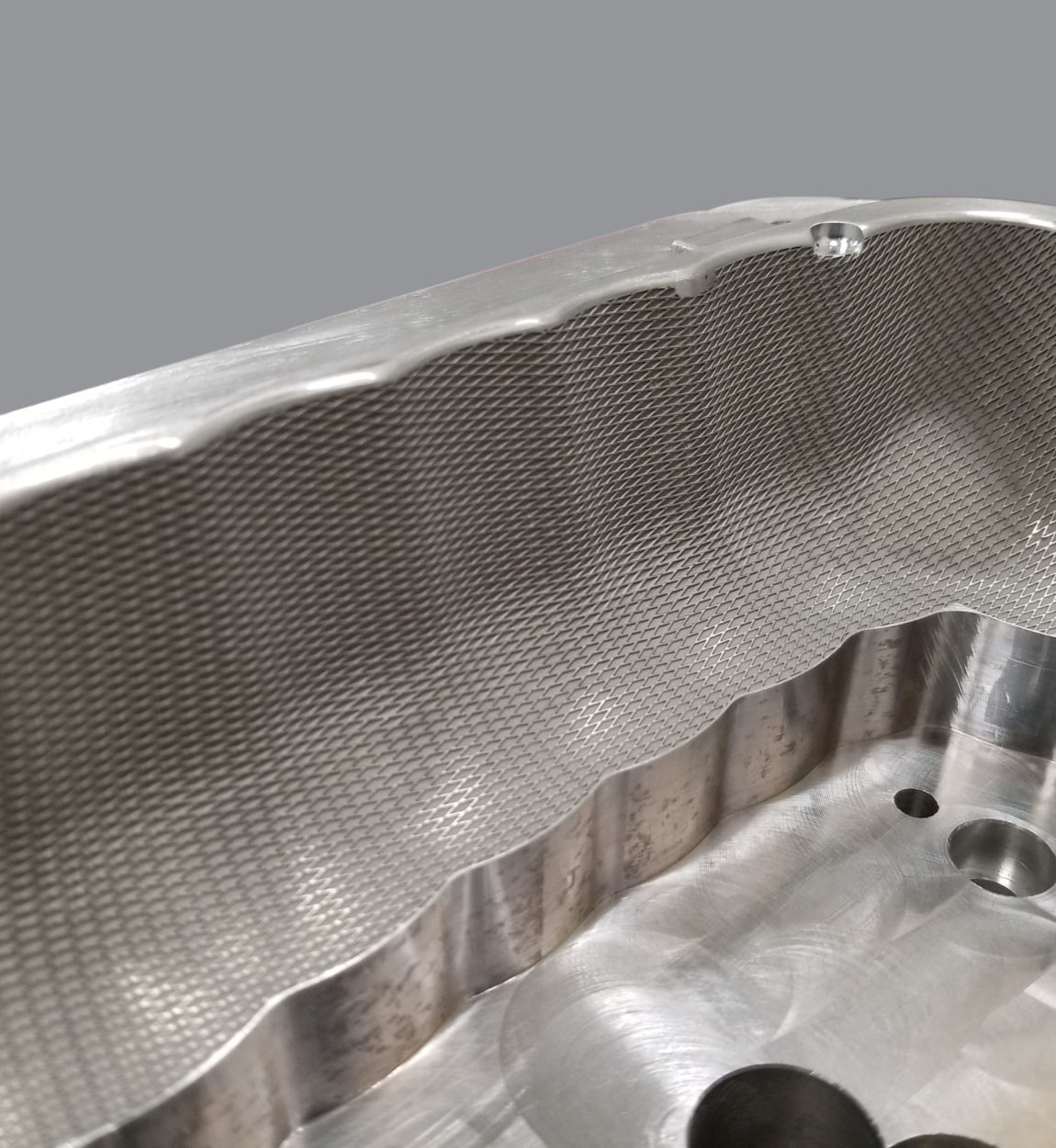

Within our inspection room at SPE we utilize profilometer technology to closely analyze the surface texture applied for each application to guarantee quality standards for our customer.

At St. Paul Engraving it is our promise to our customers to deliver on unbeatable quality, customer service & turn-around times. In order to do this we hold the highest of standards during our inspection process for each application. Whether it’s analyzing a texture of an injection mold that needs to be replicated or post texture quality inspection we utilize profilometer technology to help us closely examine surface finishes. With this technology we are able to measure: roughness, finish, texture, grain, geometry, shape, height, thickness, volume, area, flatness & warpage of any mold.

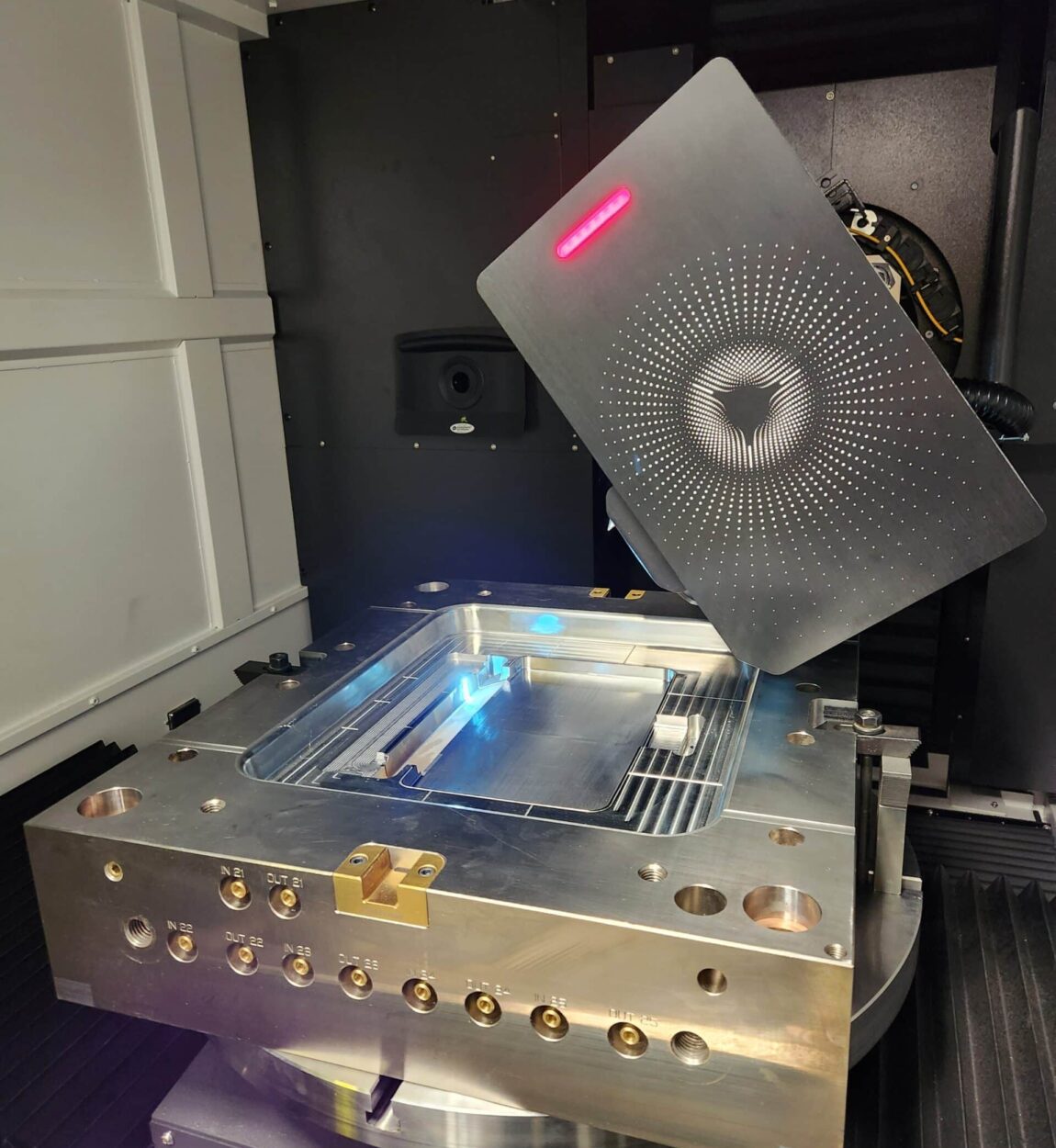

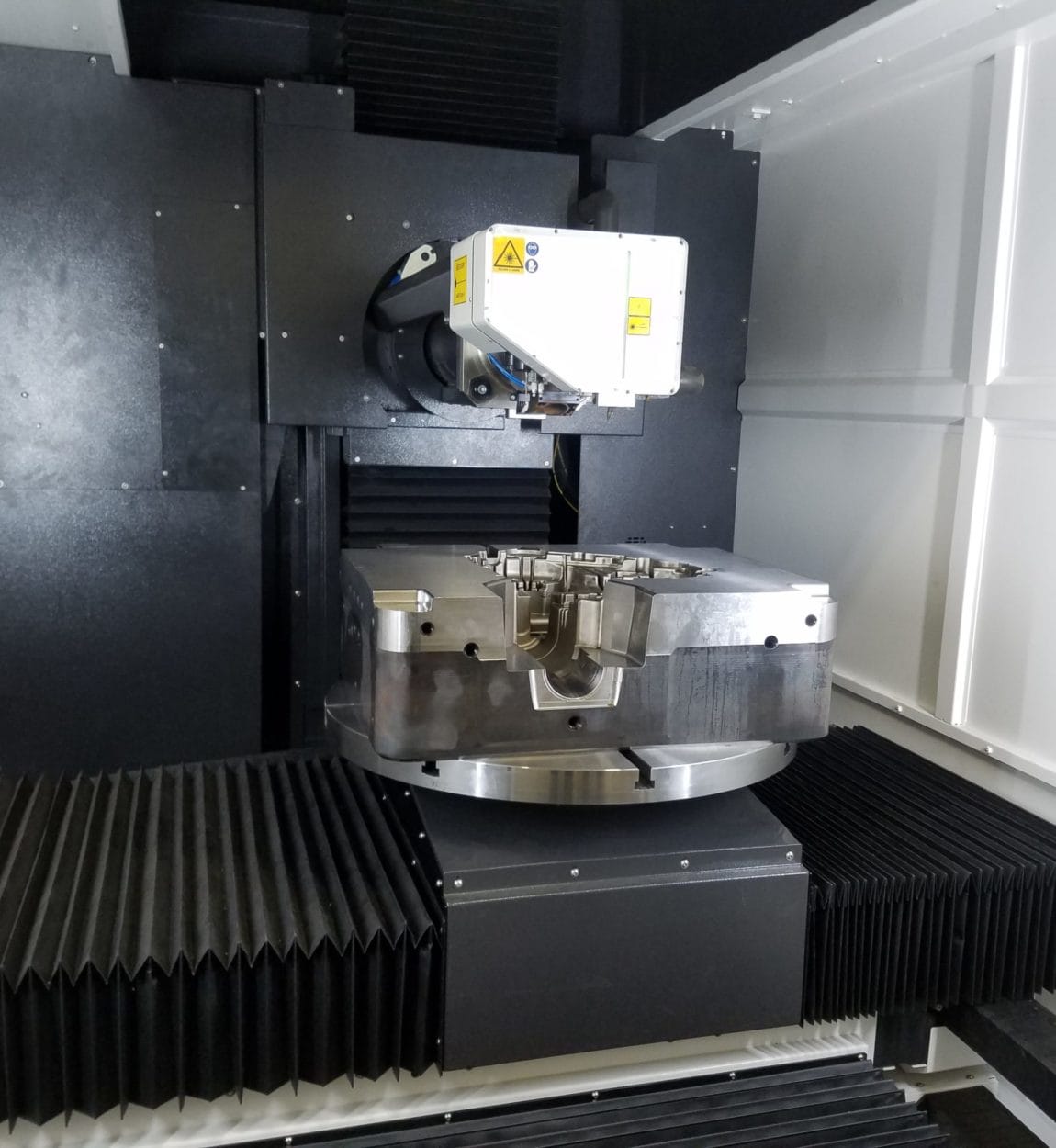

Laser S Series 1200 U w/ Femtosecond (FS)

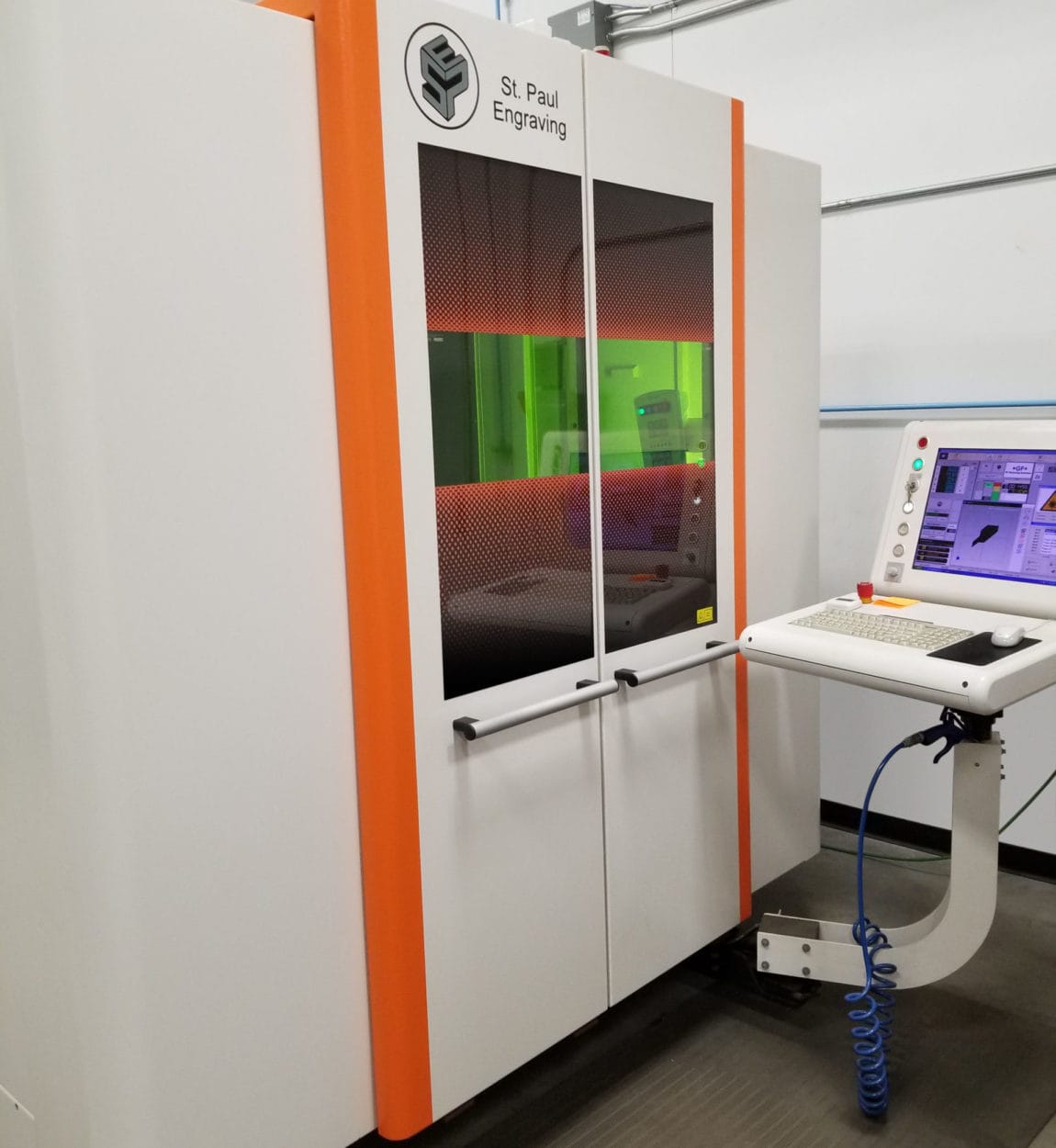

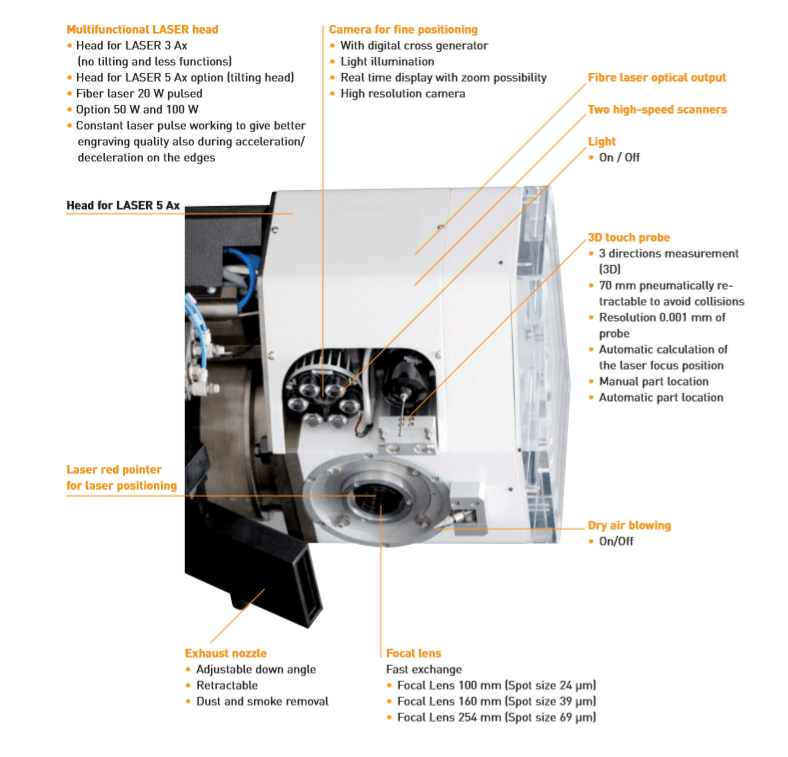

Our latest addition to the SPE shop room floor in 2024 is the the state-of-the-art 5 axis laser, Laser S Series 1200 U w/ FS.

To better serve our customers and to continue to show our dedication to innovation and advancement we’ve added the S Series 1200 U w/ FS capabilities in which unlocks the ability to redefine the standards of precision, efficiency, and quality in the plastic injection molding industry. The introduction of the Laser S Series 1200 U FS is more than just an upgrade of technology; it’s a catalyst for innovation. It’s advanced features empower designers and manufacturers to push the boundaries of what’s possible, enabling the creation of more complex, durable, and innovative products. To learn more about this technology, check out our article Revolutionizing Plastic Injection Molding: Laser S Series 1200 U Femtosecond.

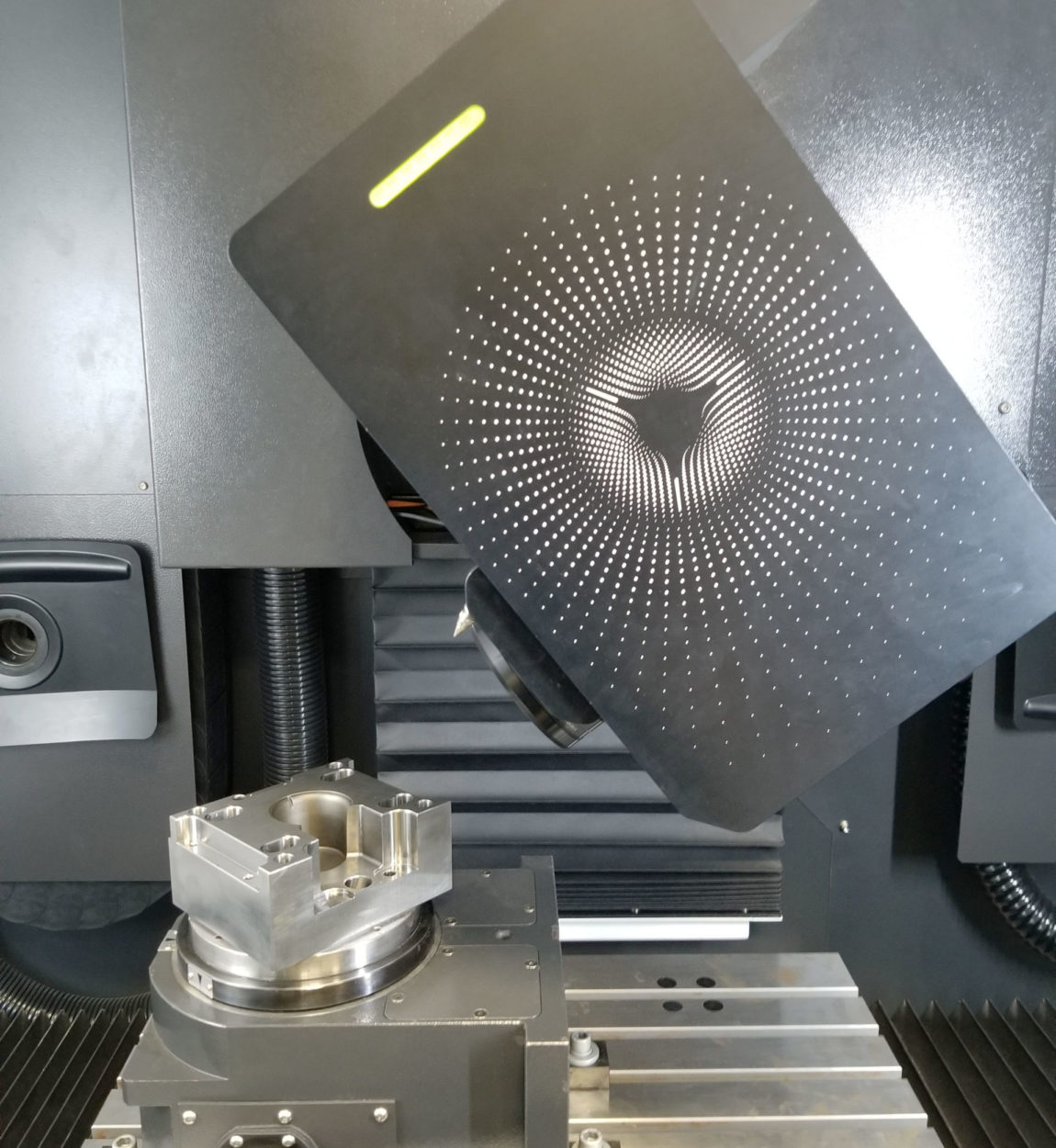

3R Workpartner +

SPE is a proud operator of the 3R system technology, Workpartner +.

To better serve our customers and to continue to show our dedication to quality, service and project turn around we added the Workpartner +. A robotic 3R dynafix and macropallet changing system allows us to enhance our 24/7 operating capabilites. The utilization of the 3R system greatly benefits applications that are high volume and have repeatable setups.

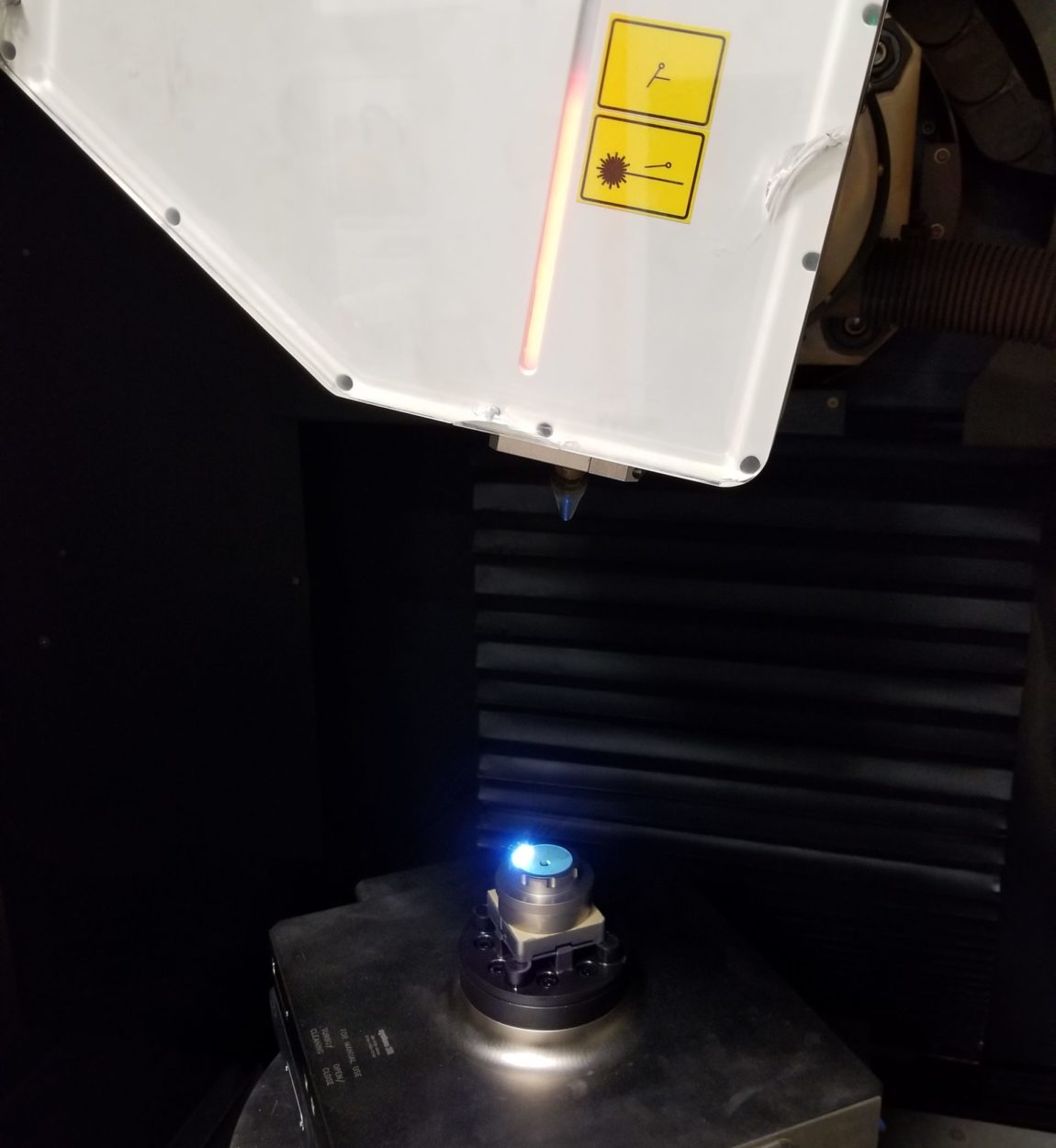

Laser S 600

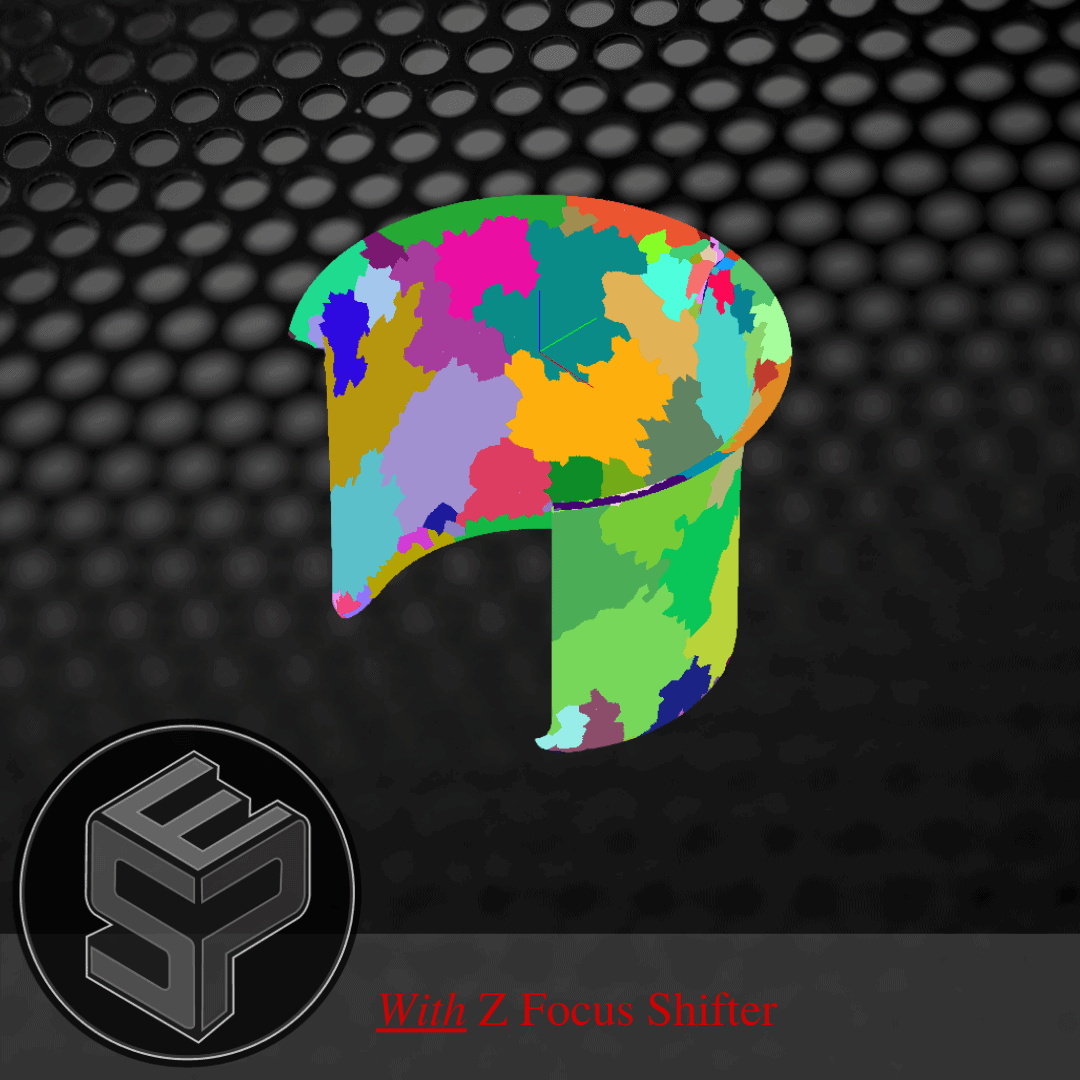

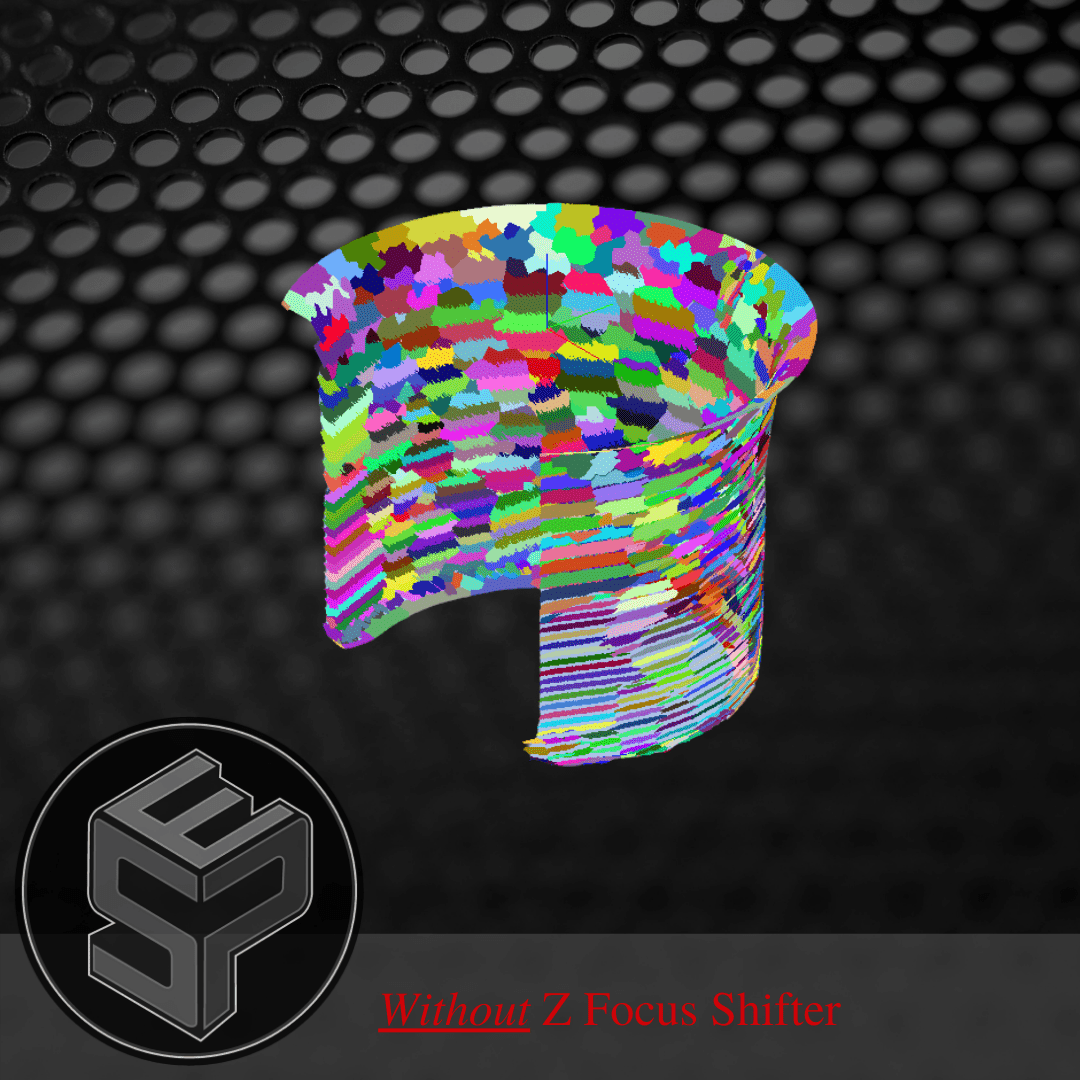

Our latest 5 axis laser S 600 series machine was added to our family of lasers in 2020. The laser S series offers unparalleled agility without compromising product quality or efficiency. The laser S 600 utilizes a Z focus shifter and dual flexi-pulse sources; paired with a robotic 3R dynafix and macro pallet changing system we are able to provide 24/7 operating capabilities.

Capabilities include:

- Smartpatch innovation coupled with Laser S hardware capabilities pushes performance further allowing optimization of the best five-axis laser texturing solutions to meet all your laser texturing demands.

- Twin laser sources for unprecedented agility.

- High speed 3D scanning system

- Multi-process solution. Executing Laser Blasting, Laser Structuring, Laser Engraving, Laser Machining, Laser Texturing & Laser Marking all at full speed and on the same laser, accelerating productivity.

- Z focus shifter; the Z focus of the beam changing to match the contour of the mold without the machine axis actually moving. This reduces the number of machine positions to complete a project while increasing the patch size at the same time.

- Dual flexi-pulse sources; adds the ability to adjust the pulse duration from 4-200 microseconds. This allows for greater control of surface finish while minimizing burr or recast and reducing micro fracturing, which is ideal for medical and optical parts. Having dual sources allows us to switch between a 100-watt source and 30 watt source to achieve unprecedented surface finishes without compromising on time or quality.

Laser 1000

Featuring an automated palletizing system allowing us to run/produce 24 hours in a day.

This machine has a 50 watt laser source that is ideal for laser texturing and engraving small consumer goods, small bottle molds, medical tools, and small automotive parts with high detail and precision. Maximum work piece is 12 in. x 12 in. x 12 in. Maximum weight is 330 lbs.

Laser 1200

Laser series 1200 which is ideal for medium to large components, multi-cavity molds, automotive molds and much more.

Capabilities include:

- 100 watt source for faster material removal rates on large mold components.

- Maximum weight of 3,748 lbs and max workpiece is up to 60″ x 48″ x 36″ (depending on the application).

The laser series 1200 offers the unique ability to laser texture molds while still assembled.