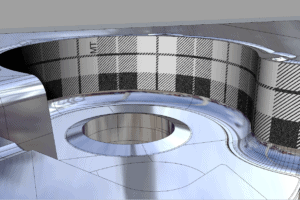

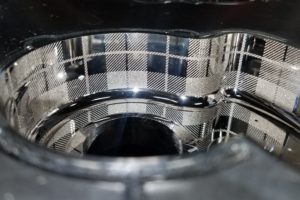

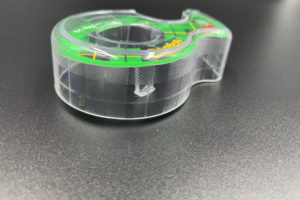

Scotch Tape

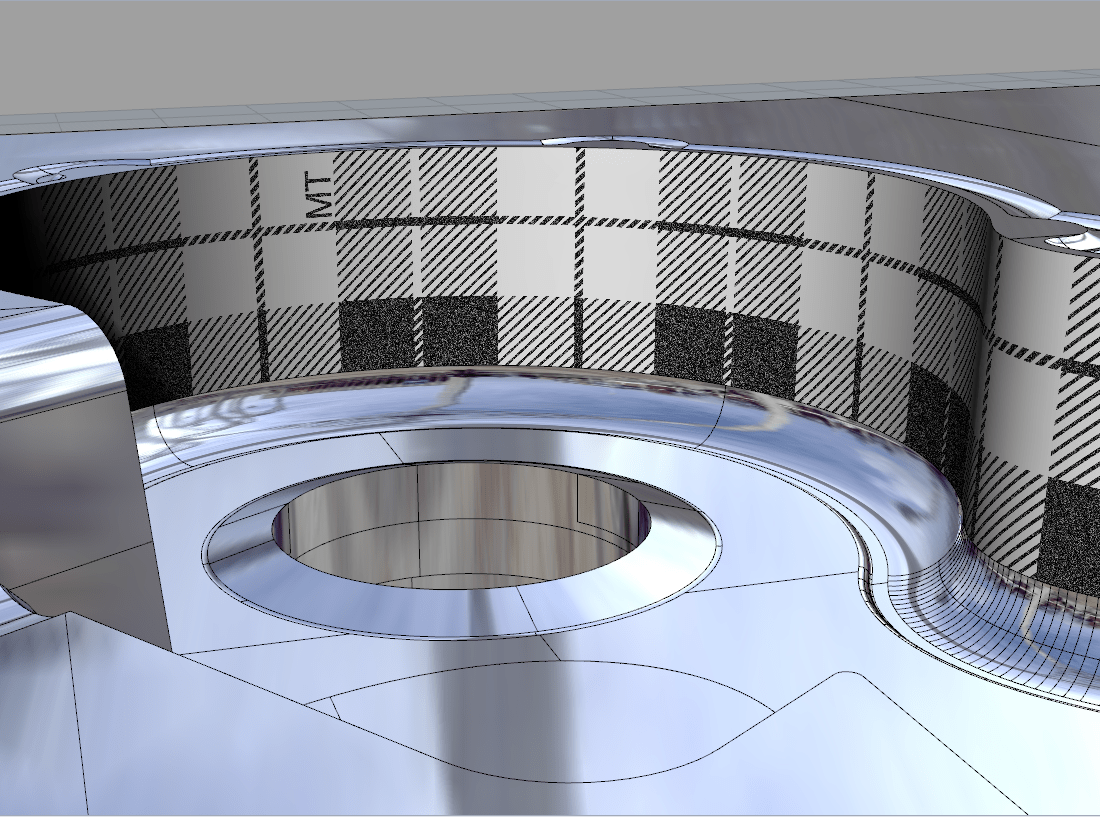

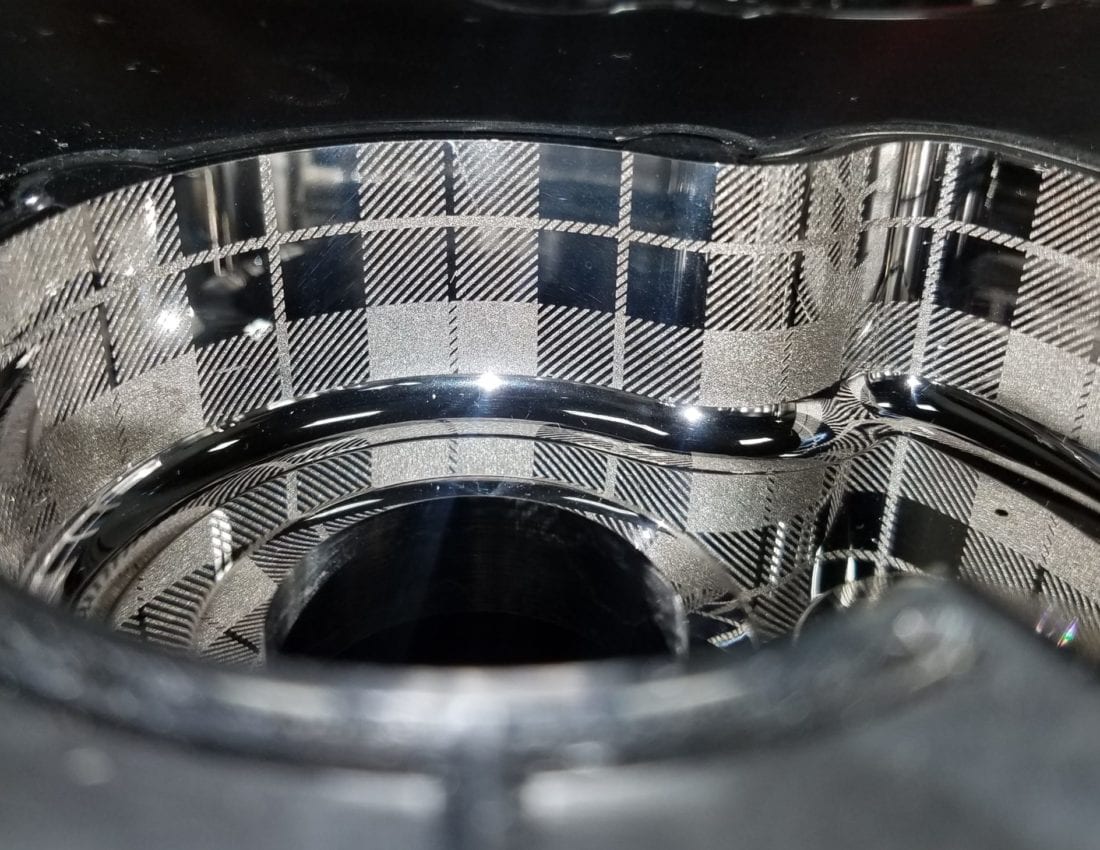

In this application example, St Paul Engraving utilized our 5 axis laser 1000 combined with our automated pallet changing system. We laser textured the iconic plaid pattern into the sidewall of the mold on this multi-cavity tool. We then engraved the Scotch text into separate mold inserts. Lastly we engraved electrodes to burn the recycle logo into the mold cavities. Being a clear part, this project presents challenges as all cavities require a high shined finish. However, laser texturing is a clean process producing repeatable precision results eliminating the risk of damaging the high shine finish. A high-volume, multi-cavity project like this can take time to be completed; however, using our automated palletizing system we are able to run 24/7 significantly decreasing our turn around time.