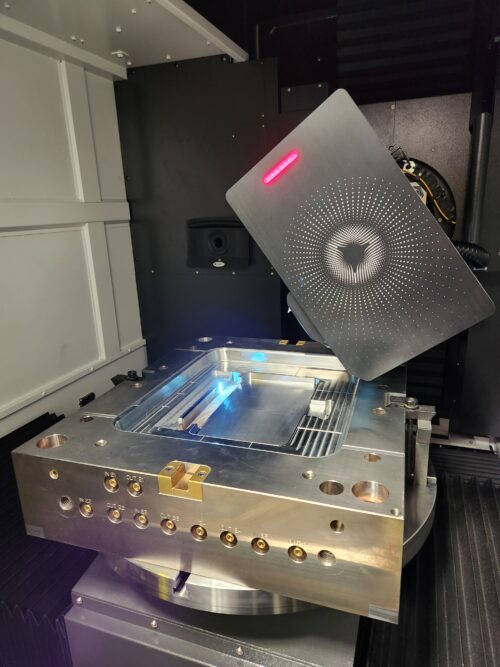

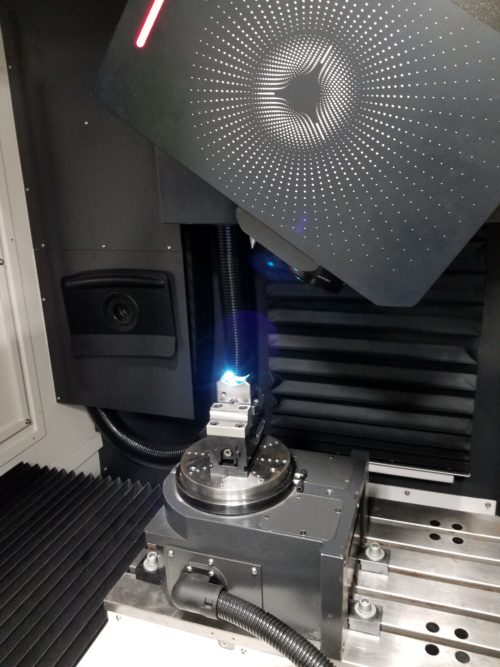

Revolutionizing Plastic Injection Molding: Laser S Series 1200 U Femtosecond

In the rapidly evolving world of manufacturing, staying ahead of technology curves is not just an advantage; it’s a necessity. St. Paul Engraving is thrilled to announce a game-changing addition to our shop: the Laser S Series 1200 U with Femtosecond (FS) capabilities. This state-of-the-art 5-axis laser technology is set to redefine the standards of precision, efficiency, and quality in the plastic injection molding industry.

Unmatched Precision and Versatility

The Laser S Series 1200 U FS is engineered for excellence, offering unparalleled precision in material processing. Its 5-axis capabilities enable complex geometries and intricate designs that were previously unachievable, opening up new possibilities in mold design and production.

Femtosecond Laser Technology: A Leap Forward

At the heart of the Laser S Series is its femtosecond laser technology, which emits ultra-short pulses to ablate material with extreme accuracy and minimal thermal impact. This means cleaner cuts, finer details, and reduced post-processing requirements, significantly enhancing product quality and reducing turnaround times.

Boosting Efficiency and Reducing Costs

Efficiency is key in manufacturing, and the Laser S Series excels in this area. Its advanced laser system streamlines the production process, reducing material waste and energy consumption. By minimizing the need for manual finishing and correction, it also lowers labor costs, making high-quality production more affordable.

Opening New Doors for Innovation

The introduction of the Laser S Series 1200 U FS is more than just an upgrade of technology; it’s a catalyst for innovation. It’s advanced features empower designers and manufacturers to push the boundaries of what’s possible, enabling the creation of more complex, durable, and innovative products.

The future of plastic injection molding is bright, and with the Laser S Series 1200 U FS, St. Paul Engraving is at the forefront of this technological revolution. Embracing this cutting-edge technology not only enhances our capabilities but also reaffirms our commitment to delivering exceptional quality and value to our clients.