PTXPO 2023 – Rosemont, Illinois

Comments Off on PTXPO 2023 – Rosemont, IllinoisPlastics Technology Expo – Will we see you there?

“PTXPO 2023 is a dynamic tradeshow created for decision makers paving the way for plastics processing throughout the entire North American supply chain.”

– PTXPO, 2023

St. Paul Engraving is excited to announce that we will be attending PTXPO, March 28-30, 2023 at the Donald E. Stephens Convention Center in Rosemont, Illinois.

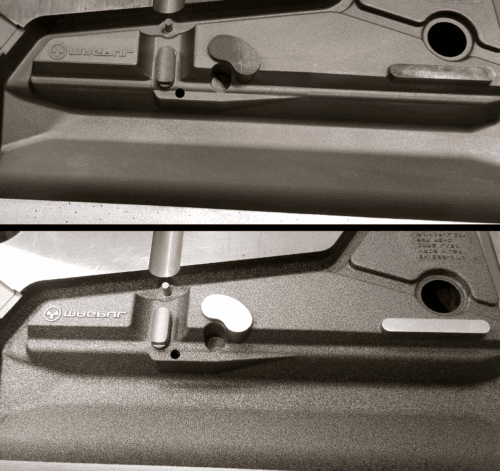

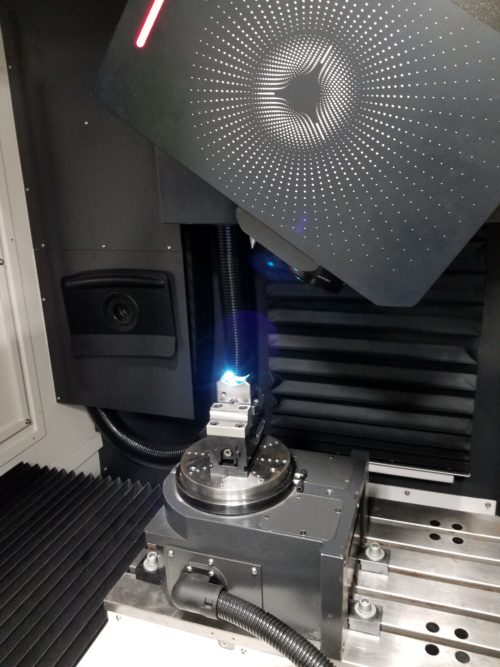

At our PTXPO booth, we will be able to collaborate with fellow plastic injection molding manufacturers on how laser texturing/engraving, chemical texturing/engraving & specialty services helps transform the mold manufacturing industry. We are here to help answer any/all question as it relates to your mold finish solutions.

We look forward to meeting you!

Video Credit: PTXPO Home Page 2022